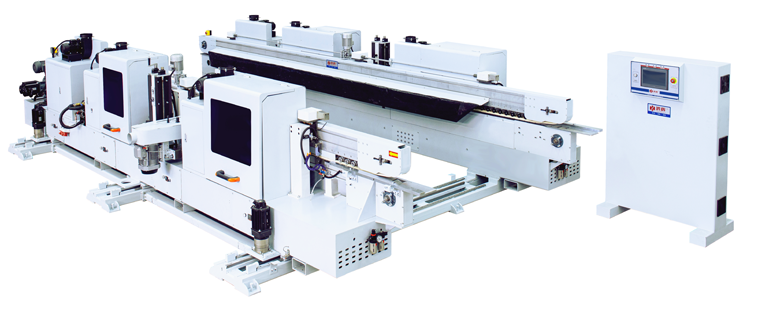

滚边机E款 (双端辊喷)

型号:HL-G100E(定制型)

HL-G100E(定制型)(辊喷可结合)

双端UV辊边机是一种用于对大型板材两端进行UV辊边处理的设备

功能作用:

可对板材两端同时进行砂光、涂布UV漆及固化处理,能提高漆膜附着力和对基材的支承作用,还可实现边部铣型、倒角等,替代传统封边条,提升产品环保性能。

工作原理:

通过输送系统将板材送至工作区域,利用砂架对板材两端进行砂光,再经辊涂装置将UV漆均匀涂布在板材端部,最后通过UV固化系统使油漆快速固化。

设备特点:

通常具有自动砂光、自动涂布、快速固化等功能,可实现连续作业,提高生产效率,且能适应不同形状和材质的板材,部分设备还可根据生产工艺定制。

Double end UV roller edge machine is a device used for UV roller edge treatment on both ends of large sheets

Function: It can sand polish, apply UV paint and cure both ends of the board at the same time, which can improve the adhesion of the paint film and support the substrate. It can also achieve edge milling, chamfering, etc., replacing traditional edge banding and enhancing the environmental performance of the product.

Working principle: The board is transported to the work area through a conveying system, and the two ends of the board are sandblasted using a sand rack. Then, the UV paint is evenly applied to the ends of the board through a roller coating device, and finally, the paint is quickly cured through a UV curing system.

Equipment features: It usually has functions such as automatic sanding, automatic coating, and rapid curing, which can achieve continuous operation, improve production efficiency, and adapt to different shapes and materials of boards. Some equipment can also be customized according to production processes.

展厅:佛山市顺德区红力机械设备有限公司

展厅:佛山市顺德区红力机械设备有限公司 工厂地址:佛山市顺德区伦教街道新塘村世龙集约工业区世龙大道27号之2

工厂地址:佛山市顺德区伦教街道新塘村世龙集约工业区世龙大道27号之2

服务热线:+86 0757-27751889 (20条服务热线)

服务热线:+86 0757-27751889 (20条服务热线)

公司网址:

公司网址: