线条双头真空喷涂线(四面喷涂)

型号:HL-Z300E / HL-Z400E

HL-Z300E / HL-Z400E

真空喷涂的原理是利用真空技术,通过密闭容器内的高压泵压送涂料,高压的涂料高速喷出,随着压力骤降,UV涂料骤然膨胀并雾化,将涂料均匀包覆在工件表面。喷涂过程在封闭的箱体内进行,雾化稳定,所形成的涂膜均匀、平整。真空喷涂机目前主要应用于木制品行业,是家具门窗线条、百叶、圆棒等有沟槽的直线条状工件喷涂设备,一次完成整个工件的四面喷涂。双真空系统,满足不同工艺需求,提升作业便利性。

The principle of vacuum spraying is to use vacuum technology to pump paint through a high-pressure pump in a closed container. The high-pressure paint is sprayed out at high speed, and as the pressure drops sharply, the UV paint suddenly expands and atomizes, evenly coating the surface of the workpiece. The spraying process is carried out in a closed box, with stable atomization and a uniform and smooth coating film formed. Vacuum spraying machines are currently mainly used in the wood products industry. They are equipment for spraying straight and strip-shaped workpieces with grooves, such as furniture door and window lines, louvers, and round bars. The entire workpiece can be sprayed in one go.The dual nozzle can be used for transparent primer and mixed oil primer, eliminating the need to clean the fuel tank and pump.

生产线工艺流程

Production line work

上料→双头真空喷涂机 → UV干燥机 → 输送机

Paper → Double head vacuum spraying machine → UV drying machine → conveyor machine

产品特点

Product Features

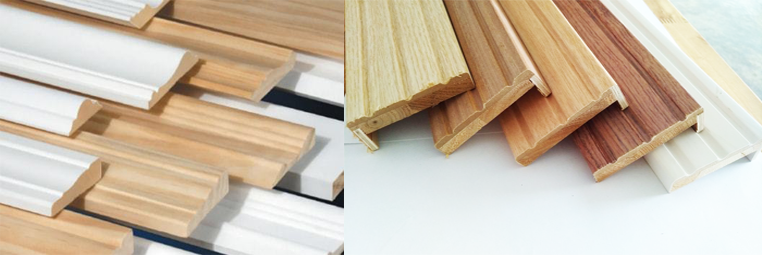

适用于门框、门线、画框、窗帘架、舌槽企口板、门窗配件、地脚线、地板等条状工件连续自动喷涂。此机可针对UV、水性涂料进行大批量连续涂装,喷涂均匀,油漆利用率100%,本机采用不锈钢机身,耐酸碱。若喷涂水性涂料可与横向平移干燥机配套使用,干燥效果更佳。

Designed for furniture lines, frame, curtain rod, a gate line, stude screws line, floor, and various kinds of complex product line profile, spraying water paint or UV light curing primer, water-borne UV paint materials and professional design. Spray coating process are carried out within the vacuum box, paint 100% recycled, UV primer or paint drying, to speed up the paint curing time, save energy and improve production efficiency

展厅:佛山市顺德区红力机械设备有限公司

展厅:佛山市顺德区红力机械设备有限公司 工厂地址:佛山市顺德区伦教街道新塘村世龙集约工业区世龙大道27号之2

工厂地址:佛山市顺德区伦教街道新塘村世龙集约工业区世龙大道27号之2

服务热线:+86 0757-27751889 (20条服务热线)

服务热线:+86 0757-27751889 (20条服务热线)

公司网址:

公司网址: